Drying & Firing - Waste Heat Drier & Tunnel Kiln is used for brick production and needs 380V voltage. This kiln is known to deliver a high production rate, apart from having an automatic and digital system. Some of the key features of this drying and firing kiln are large heat utilization space, fuel efficient mechanism, adjustable temperature and simple operating method. Drying & Firing - Waste Heat Drier & Tunnel Kiln need less physical labor to run along with requiring a little maintenance. For large volume manufacturing, it also has reduced investment costs per piece in terms of energy and machinery. We are manufacturer, supplier and exporter of this kiln and provide it in the markets of Kolkata, Howrah, Delhi, Assam, Mumbai, India, Middle East, Asha, South America, and Europe.

Yes! I am Interested Learn More

Apocalypse Steel And Power Limited is a Kolkata based supplier of high quality 60 Percent Alumina Bricks to clients for corrosion free service. The bricks have a higher capacity to resist heat and any other chemical erosion. Our alumina bricks are known for bringing strength, thermal stability and slag withstanding capacity to the furnace or wherever they are used. Clients residing in the markets of the Middle East, Asia, South America, Europe and India demand Apocalypse 60 Percent Alumina Bricks for application in cement lime industry in shaft kiln, lime rotary kiln, and pre-burning zone. We produce High Alumina Bricks 60% AL2O3 by using two elements that are Bauxite and Clay Grog. These bricks have excellent abrasion resistance along with higher refractoriness. Their R.U.L. (Refractoriness Under Load) is 1420 °C, whereas A.P. (Apparent Porosity) is 23%. Apart from this, the 60% Alumina Bricks have 2.50 g/cc as their Bulk Density (BD) and 400 Kg/cm2 as the Cold Crushing Strength (CCS

Yes! I am Interested Learn More

Apocalypse Steel And Power Limited is among the top class suppliers and manufacturers of Sillimanite Bricks. These are prepared from specially selected minerals of sillimanite & aluminum silicate with water as liquid carrier. In their production process, the high-temperature firing method or slurry casting is used. These processes result in creation of quality refractory bricks refractory bricks that are strong and resistant to wear at high temperatures, making them ideal for use in high-temperature furnaces including blast furnaces, hot blast stoves, lime kilns, and glass melting furnaces, among others. These special bricks are mainly used for the molding of glass furnaces. Whether you need Sillimanite Brick in Delhi or Ahmedabad or any other Indian city, we can fulfill your requirements. In fact, we are internationally rated among the top Sillimanite Bricks Dealers that offer the best combination of quality and price which is needed in the applications.

Yes! I am Interested Learn More

Based in Kolkata, we are manufacturing and exporting Blast Furnace Bricks For Iron & Steel Industry. These bricks work as a solution for the lining of bricks that are used in the blast furnace while forging the iron and steel. In other words, these are commonly used in the furnace bricks and the furnace stacks which are mainly impacted by the wear and chemical deposition erosion. We are open for large orders for these bricks and assure timely delivery anywhere in India or in the Middle East, South America, South Europe and Asia. The Blast Furnace Bricks For Iron & Steel Industry have good thermal conductivity. These bricks for furnaces are also known for having superior fire resistance and compressive strength. Also known as super duty fireclay bricks, these are also suitable for the applications in the segments of steel and iron.

Yes! I am Interested Learn More

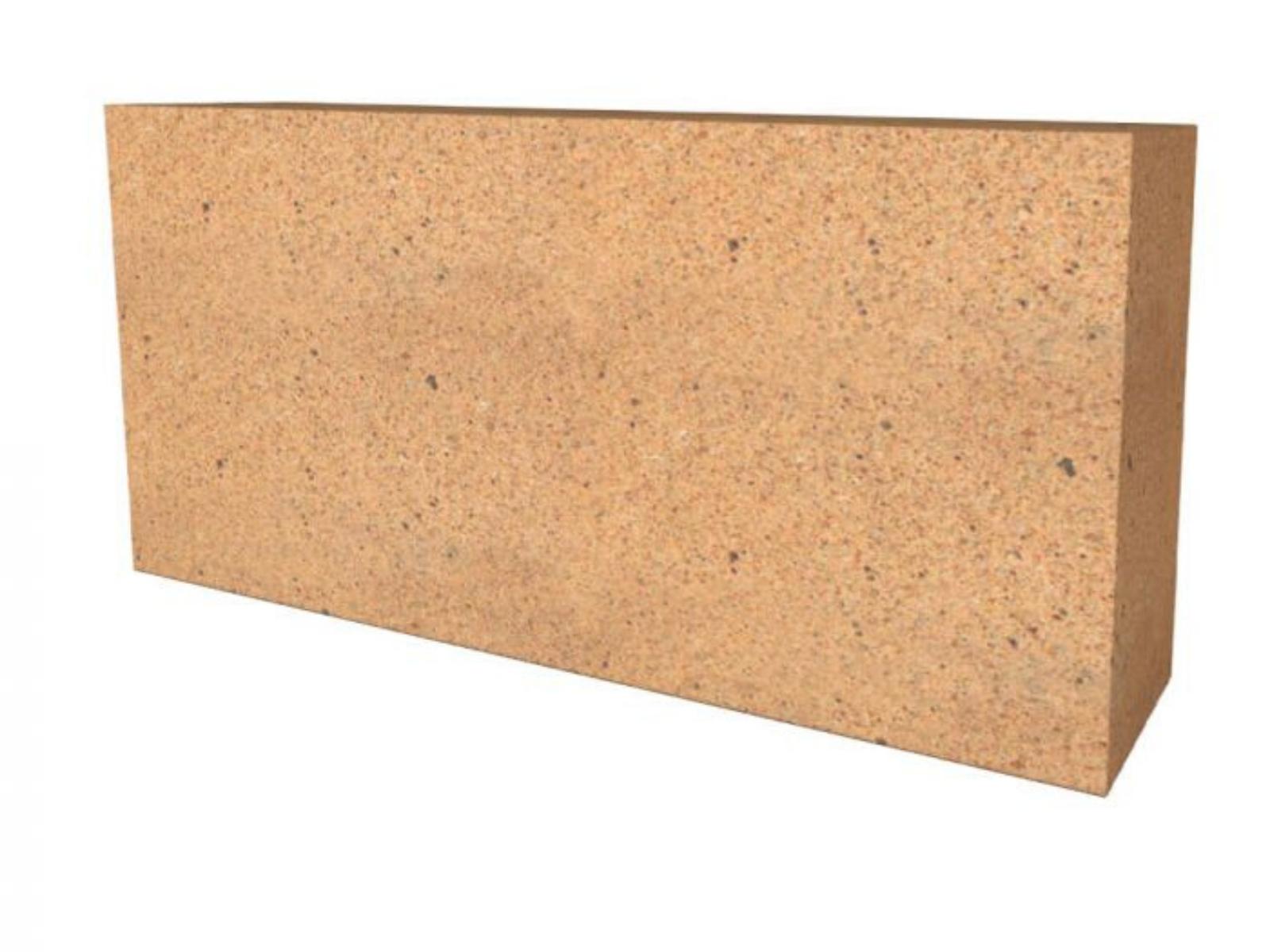

Renowned for their excellent mechanical strength and supreme temperature resistance, fire bricks are offered by us. We are among the leading Fire Bricks Manufacturers & Suppliers in Kolkata delivering the fireproof bricks in the markets of Howrah, Delhi, Assam, Mumbai, and other parts of India. These are used for blast furnace stoves and have the capability of taking heavy loads. Manufactured using a sintering method, these bricks are acidic and possess thermal stability. Highly durable because of the magnesia/silica based properties, these are demanded in the markets of Middle East, Asia, South America and Europe. Fireclay is heated in a kiln to a partially vitrified state before being used to make firebrick. The brick might also be glazed for certain uses. It finds application in boilers and furnaces. We offer the best fire bricks in Kolkata that are made for withstanding higher temperatures and optimum energy efficiency because of its less thermal conductivity.

Yes! I am Interested Learn More

We are supplying and exporting precast pre-fired blocks for burners from Kolkata, India, with complete quality assurance. These blocks are provided with +1 mm dimensional tolerance. These precast blocks have a maximum 2500 kg/cm2 compressive strength. In addition to this, the burner blocks have shape feasibility in between 500 grams to 10 tons. Their primary features are reduced production costs and environmentally beneficial content. Apart from this, the precast pre-fired blocks for burners are known for the salient features such as excellent dimension tolerance, unparalleled compressive strength, heightened defense against alkali assaults and ability to withstand impacts, abrasions, thermal shocks, creep, and degradation. The burner blocks are exported to Asian and Middle East markets.

Yes! I am Interested Learn More

A horizontal anode baking furnace, Aluminum Industry For Anode Baking Furnace, aluminum industry, Kolkata, India , middle east, Asia. The impact of degraded refractory-wall thermal conductivity on the baking process is also investigated and it was found that the material properties degradation for an aged furnace must be addressed accordingly. Anode baking is an important step for producing high-quality aluminum cathodes.

Yes! I am Interested Learn More

Apocalypse Steel And Power Limited is a leading supplier & exporter of checker bricks. These are commonly used in the steel and iron industry. It is a type of heat carrier used in hot blast stoves of blast furnaces and flame furnaces because of its outstanding high temperature load creep capability, high density, and minimal apparent porosity. Also known as construction bricks, ACC bricks, checkered bricks or solid bricks, these are offered at the best prices throughout India (especially Delhi, Kolkata) and internationally to the Middle East countries, Europe, America, and Asian countries. In the said industries, these products are used in the annealing furnace, cupola furnace, heat treatment furnace, refining furnace, metal mixer furnace, induction furnace, and others. For high quality refractory checker bricks for blast stove, we are trusted as the manufacturer from India.

Yes! I am Interested Learn More